Now Reading: Innovative Humanoid Robot: Driving Industrial Automation

-

01

Innovative Humanoid Robot: Driving Industrial Automation

Innovative Humanoid Robot: Driving Industrial Automation

Innovative Humanoid Robot: Driving Industrial Automation

In today’s fast-paced industrial landscape, the integration of advanced technology is paramount. A cutting-edge humanoid robot is set to revolutionize industrial automation by blending robotics, AI, and IoT in manufacturing to overcome workforce challenges and boost productivity.

The Rise of the Humanoid Robot in Industrial Automation

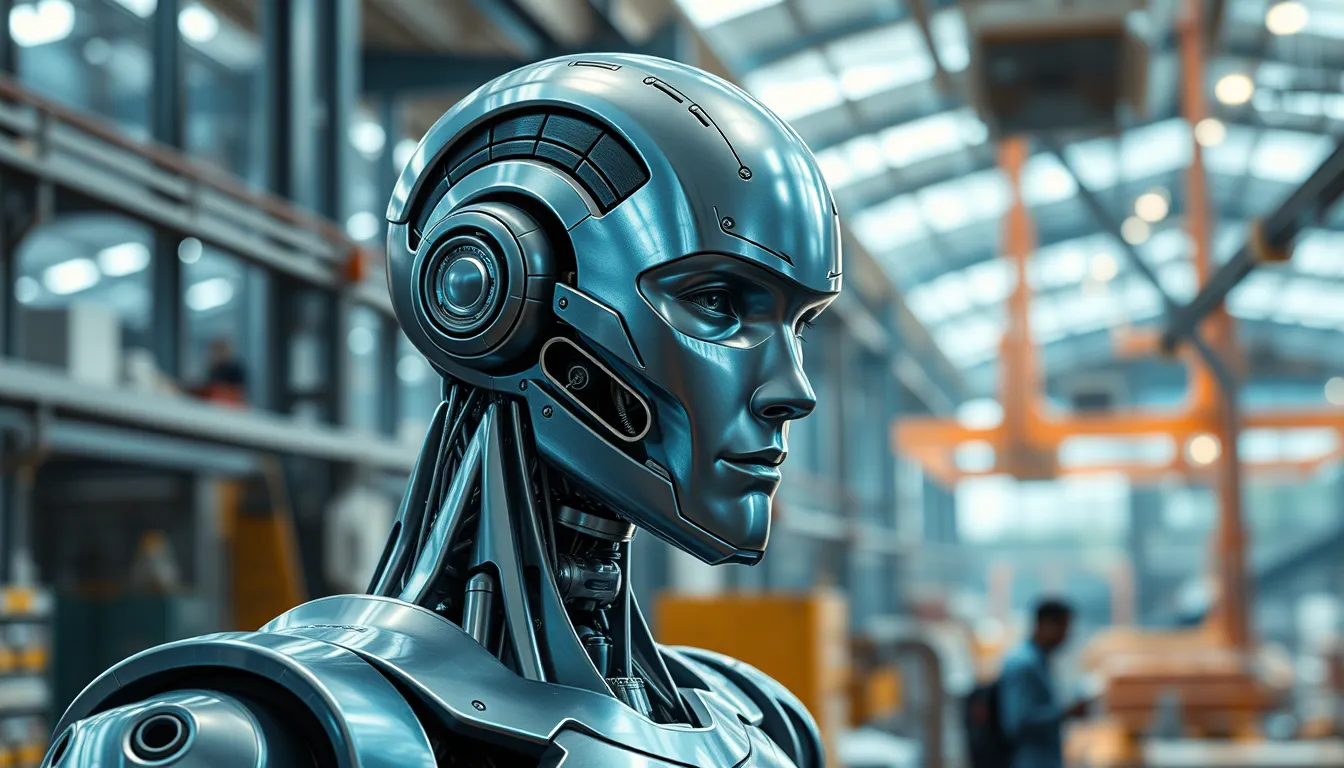

Recent advancements in robotics have paved the way for the development of a highly sophisticated humanoid robot. Engineered to mimic human dexterity and cognitive abilities, this humanoid robot is designed for operational efficiency across multiple sectors. With the backing of leading innovators like Hexagon Aeon Industrial Robotics and powered by Nvidia AI technology, the robot is a symbol of the future of industrial automation.

Key Features and Technological Integration

The humanoid robot has been outfitted with a range of features that make it a game-changer for manufacturing environments:

- Precise mechanical and cognitive functions—allowing it to perform complex tasks with minimal error.

- Real-time data processing and machine learning capabilities, courtesy of Nvidia AI technology.

- Seamless IoT connectivity that transforms traditional manufacturing plants into smart industrial ecosystems.

Additionally, the robot is equipped with advanced sensors that facilitate predictive maintenance. This capacity not only ensures continuous operational efficiency but also minimizes downtime by forecasting potential issues before they arise.

Addressing Labour Shortages with Advanced Robotics

One of the most significant benefits of deploying a humanoid robot in industrial settings is its capacity to alleviate labour shortages. With industries worldwide facing challenges from ageing workforces and rising labor costs, the introduction of this intelligent solution is timely and essential. The long-tail keyword, advanced humanoid robot for labour shortage, highlights a crucial point: this technology is designed specifically to fill gaps left by diminishing human resources.

This intelligent industrial robotics for workforce optimization is not about replacing human workers entirely but rather about augmenting their capabilities. While the humanoid robot takes on repetitive, hazardous, or highly precise tasks, human workers can redirect their skill sets towards strategy, innovation, and quality control. Over time, this symbiosis between human expertise and robotic efficiency is expected to drive significant gains in productivity and safety.

Enhancing Productivity Through Predictive Maintenance

The integration of predictive maintenance is another standout feature of this humanoid robot. Leveraging the power of IoT in manufacturing, the robot continuously gathers and analyzes data from production lines. This proactive approach helps in detecting minor anomalies before they escalate into costly breakdowns. Industries can thus maintain streamlined operations with minimal disruption. Key benefits include:

- Reduced operational downtime

- Enhanced safety in hazardous environments

- Improved quality control and product consistency

By ensuring that maintenance issues are addressed before they lead to major failures, the robot not only saves cost but also strengthens the overall resilience of industrial systems.

Strategic Impact on Modern Manufacturing

The introduction of the humanoid robot marks a turning point in modern manufacturing. The deployment of this technology is expected to catalyze a broader transformation of traditional industries into agile, tech-savvy enterprises. Industrial automation driven by this humanoid robot promises to:

- Increase overall production efficiency

- Boost safety standards by reducing direct human exposure to dangerous tasks

- Enable data-driven decision making through continuous performance monitoring

Furthermore, the advanced features of this humanoid robot serve as an inspiration, paving the way for further innovations. Its design encourages the development of new skill sets among human workers, especially in areas related to robotics programming, systems integration, and maintenance of intelligent machinery.

Future Outlook and Economic Implications

As industries continue to adapt to rapid technological changes, the role of the humanoid robot is becoming increasingly critical. Experts predict that the continuous evolution of robotics will lead to even more refined solutions that further bridge the gap between human labor and automation. There is rising optimism about the economic benefits—ranging from cost savings in manufacturing to the creation of new job opportunities in tech-driven sectors.

In conclusion, the emergence of this humanoid robot represents a landmark achievement in industrial automation. With features that include state-of-the-art artificial intelligence, robust IoT integration, and predictive maintenance capabilities, the robot is ideally equipped to handle the challenges of modern manufacturing. As industries worldwide face persistent labor shortages, this robust solution not only fills critical gaps but also sets the stage for an era of unprecedented industrial efficiency and innovation.

Explore more about the future of robotics and industrial automation by staying updated with the latest advancements and industry trends.

By embracing such transformative technologies, industries can leap forward into a new age of automation where human ingenuity and robotic precision work hand in hand for a more productive and safer tomorrow.